Decontaminating Chemical Warfare Agents with DryDecon™ Technology

Table of Contents

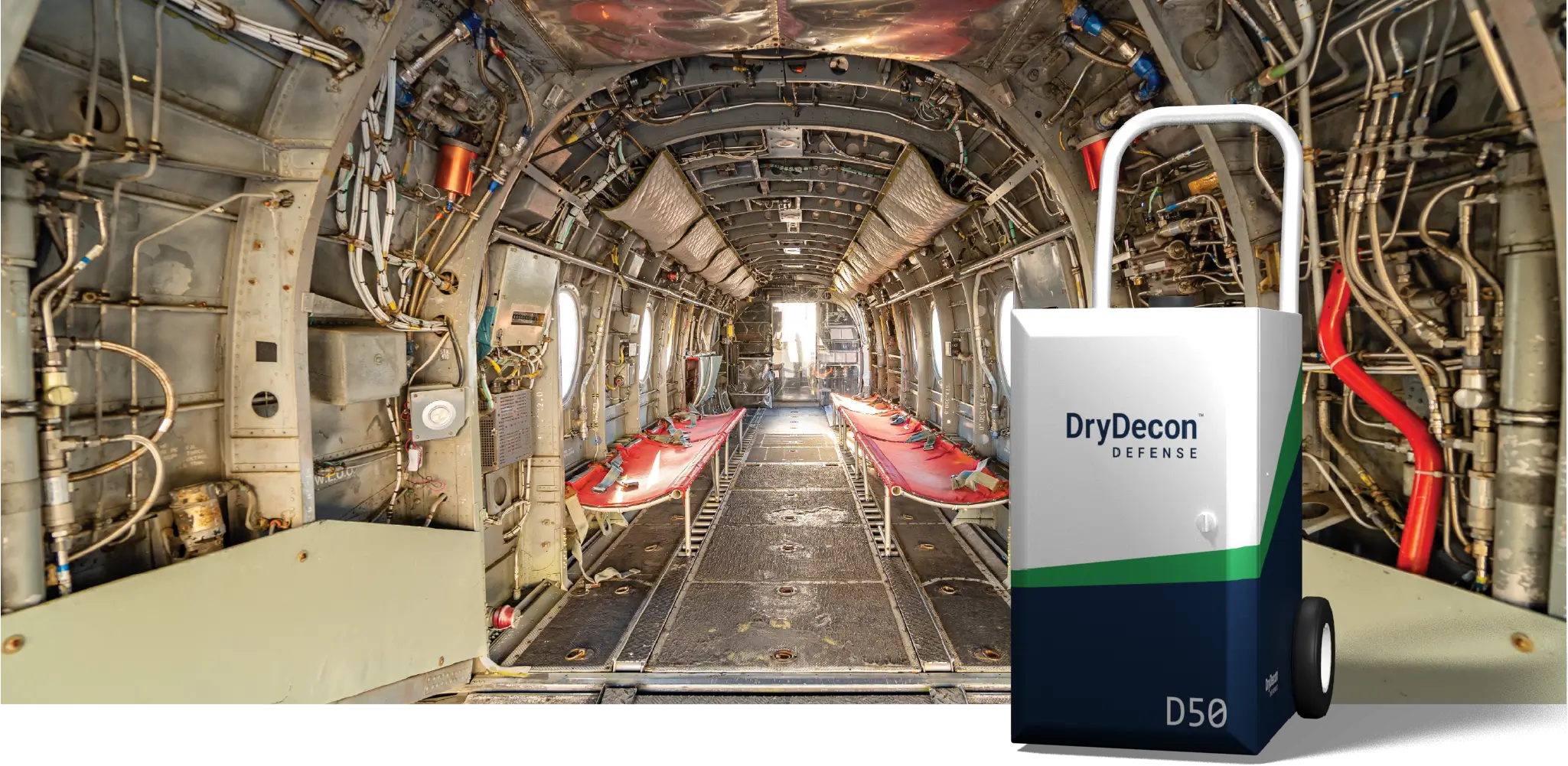

The United States faces several threats that require immediate swift and thorough decontamination, including chemical warfare agents. Our DryDecon™ Technology provides the U.S. Government with a means to address almost any chemical decontamination requirement that may arise. From office spaces to airplanes, DryDecon™ Technology has been proven to rapidly and efficiently removes nearly all residual contaminants from within an enclosed space without causing damage to equipment or electronics.

To prove the efficacy of DryDecon™ Technology against chemical warfare agents, DryDecon™ Defense successfully performed a series of tests at Avarint Laboratories using our D50 decontaminant dispersion system against samples of Sulfur Mustard (HD).

Test Procedure:

Small test coupons of four material types (CARC, military webbing, non-skid surface, and stainless steel) were contaminated with liquid HD and were allowed to weather (covered) for 60 minutes. Once fully saturated, the contaminated coupons were transferred to the decontamination chamber. Two Sensirion particle counters and one digital timer were also placed inside of the chamber to track decontamination progress.

The DryDecon™ D50 System was used to generate submicron PAA droplets/fog, which the coupons were exposed to for four hours with 1.00% (10,000 ppm) PAA.

Following decontamination, test coupons were analyzed for residual HD by solvent extraction and gas chromatography-mass spectrometry (GC-MS). Decontamination efficacy was determined by checking the percentage of residual HD remaining on or within the samples.

Results:

The table below presents the decontamination efficacy results by material type and D50 PAA decontamination exposure time.

| CARC | 4 | 2.17 | 0.37 | 0.00033 | > 99.9% |

| Non-Skid Surface | 4 | 2.17 | 1.09 | 0.325 | 85.0% |

| Stainless Steel | 1 | 1.14 | 1.00 | 0.920 | 19.0% |

| Stainless Steel | 3 | 1.14 | 0.75 | 0.253 | 77.7% |

| Stainless Steel | 4 | 1.14 | 0.77 | 0.00026 | > 99.9% |

| Military Webbing | 1 | 1.14 | 0.71 | 0.52 | 54.2% |

| Military Webbing | 3 | 1.14 | 0.49 | 0.14 | 87.7% |

| Military Webbing | 4 | 1.14 | 0.35 | 0.040 | 96.5% |

Findings:

- The D50 System demonstrated the ability to systematically deliver submicron particles and neutralize chemical agents over time without operator interaction.

- The D50 System is capable of producing submicron particles that rapidly penetrate porous material substrate and continuously neutralize chemical agents.

- During the first three hours of the decontamination cycle, a dry treatment profile was maintained (i.e., no wetting of surfaces or condensation was observed). As a result, electronics and sensitive equipment (i.e. the timer and particle counters) were not damaged by submicron particles produced by the D50 System.

- As can be seen with the stainless steel and webbing results, the HD decontamination efficacy increases significantly from the one-hour to the three-hour time point: from 19.0% to 77.7% for the stainless and from 54.2% to 87.7% for the webbing.

- By the four-hour time point, the efficacy has increased to > 99.9% and 96.5% for the stainless steel and military webbing respectively.

Conclusion:

Based on the results of our tests conducted at Avarint Laboratories, we have proven that DryDecon™ Technology is an efficacious tool for the decontamination of chemical warfare agents. In addition to removing nearly all traces of HD across four commonly used military-grade materials, the treatment area remained dry and sensitive electronic equipment was not damaged. These findings demonstrate that DryDecon™ Technology can provide the U.S. Government with a rapid and reliable means to address almost any decontamination requirement that may arise. DryDecon™ Defense is prepared to leverage our innovative technology as a tool that could be strategically deployed to rapidly, safely, and efficiently decontaminate enclosed spaces at scale. After years of research, design, development, and testing, we have assembled a system which achieves these goals and can modernizes how the United States approaches decontamination.