The Best of Conventional Gas & Fog Methods Combined!

DryDecon™ Technology converts certified decontaminant or disinfectant solutions into a submicron aerosol vapor which, due to its smaller particle size, diffuses throughout an enclosed space evenly, won’t leave surfaces wet, and removes contaminants that linger within microscopic surface cracks.

Gas

Pros

- Treats interior spaces evenly

- Reaches difficult spaces

Cons

- Uses dangerous concentrations of decontaminant

- Minimal effect on contaminants

- Requires extended exposure to be effective

- Extensive training needed

DryDecon™ Technology

Pros

- Even distribution of any certified disinfectant or decontaminant solution

- Removes contaminants in the air, on all surfaces, and within microscopic crevices

- Leaves treated area dry

- Efficient use of decontaminant

- Effective at achieving below threshold level of clean

- Lower environmental impact

- Scalable to support any requirements

- Safe concentrations are effective

- Requires minimal maintenance & user training

Fog

Pros

- Accepted as an industry standard

- Cost-effective

Cons

- Uneven distribution of disinfectant

- Large particles can’t enter microscopic crevices

- Leaves surfaces wet

- Requires technical training

- Labor intensive

- Potential damage to electronic equipment

- Less efficient in hard-to-reach areas

Gas

Pro's

- Diffuses thoroughly through a space

- No spot is missed

Con's

- Dangerous concentrations of decontaminate are required

- Minimal effect on contaminants

- Requires extended exposure to be effective

- Extensive training needed

Fog

Pro's

- Accepted as an industry standard

- Cost effective

Con's

- Uneven distribution of disinfectant

- Larger particles can’t penetrate microscopic crevices

- Leaves surfaces wet

- Require technical training

- Labor intensive

- Potential damage to electronic equipment

- Less efficient in hard-to-reach areas

DryDecon™ Technology

Pro's

- Even distribution of any certified decontaminant solution

- Removes contaminants in the air, on all surfaces, and within microscopic crevices

- Leaves treated area dry

- Efficient use of decontaminant

- Effective at achieving below threshold level of clean

- Lower environmental impact

- Scalable to support any requirements

- Safe concentrations are effective

- Requires minimal maintenance & user training

DryDecon™ Technology

DryDecon™ Technology is our patented approach to decontamination and disinfection that involves rapidly converting any certified solution into a submicron aerosol that evenly diffuses throughout an enclosed space.

Systems built using DryDecon™ Technology can reach and neutralize chemical and biological (bacterial, viral, and spore) contaminants, destroying nearly all traces of harmful agents hiding within surface cracks and microscopic crevices.

Due to being compatible with a wide range of decontaminant and disinfectant solutions, DryDecon™ Technology has the capability to serve as the primary treatment strategy for COVID-19, Avian Influenza, Clostridium Difficile (C.Dif.), Salmonella, Staphylococcus (Staph), Escherichia coli (E. Coli), Sulfur Mustard (HD), as well as various other blistering gases, nerve agents, and similar threats.

Laboratory & Scientific Validation

- First Line Technology PAA test against simulants (Oct. 2024)

- Decon Efficiency Testing: Avarint Laboratories (March 2024)

- Sewage Test (January 2024)

- Academic Testing: Fordham University (February 2023)

- Commercial Laboratory Testing: Microchem Laboratory (August 2022)

DryDecon™ Technology Explained:

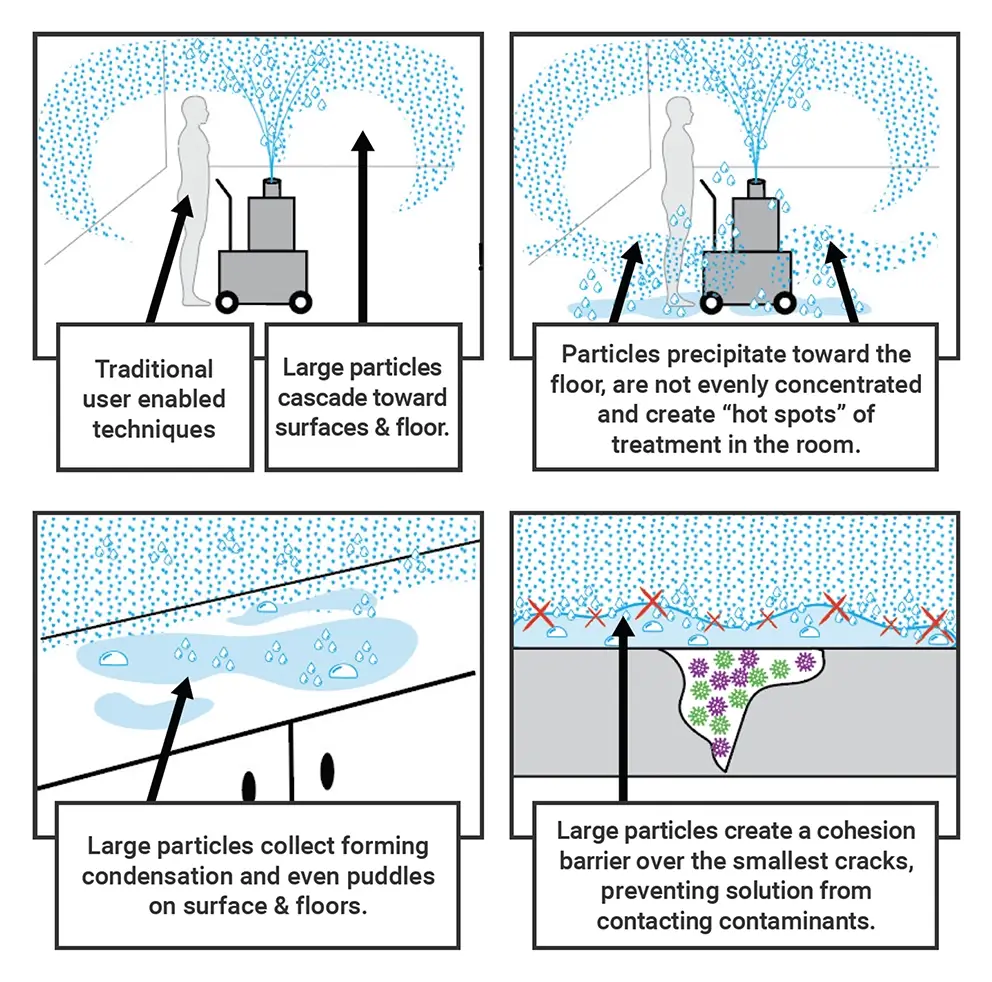

Traditional Decontamination Procedures are Obsolete

Traditional decontamination systems convert decontaminant or disinfectant solutions into a fog comprised of large particles that quickly fall to the ground after being released. As a result, dispersed particles are not spread evenly, do not penetrate deeply into surfaces, and cannot reach distant or elevated objects.

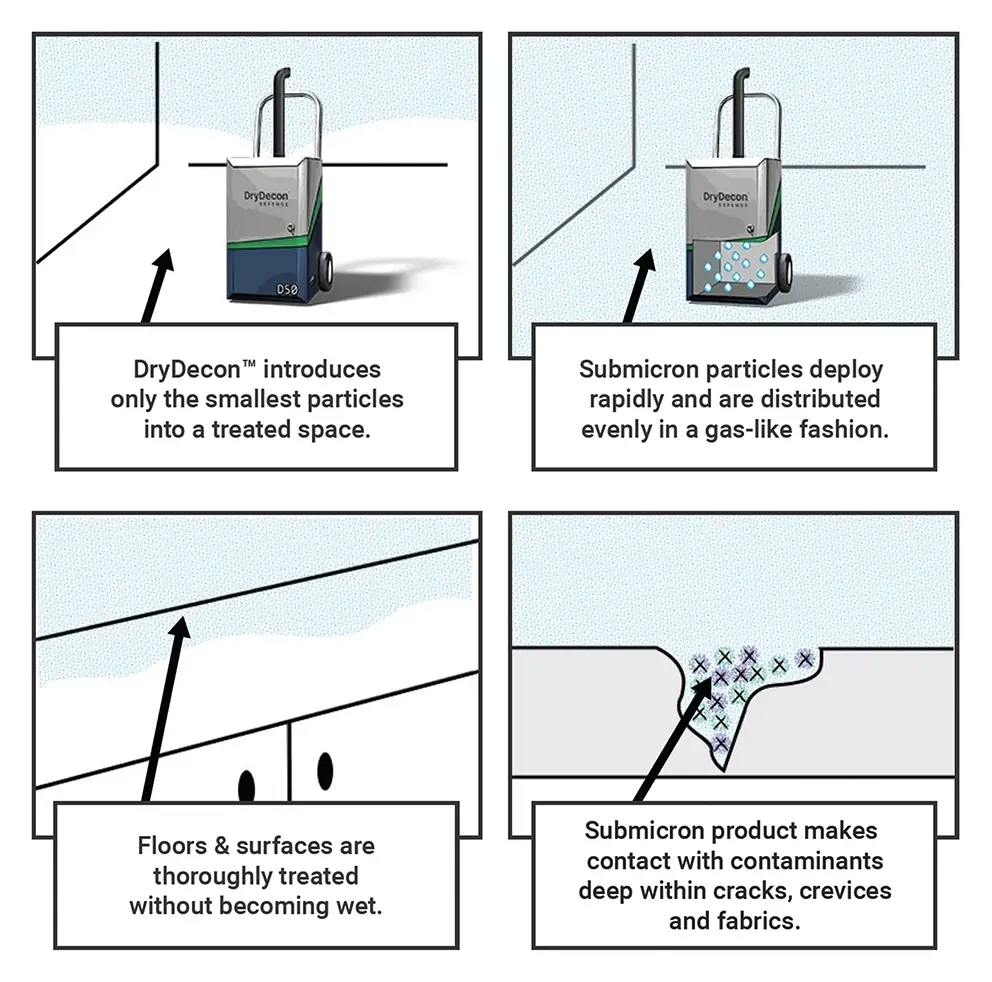

DryDecon™ Technology Solves Your Toughest Decontamination Challenges

DryDecon™ Technology resolves these issues by reducing the average size of the dispersed particles. The solution is converted into a lighter submicron aerosol vapor which spreads further and more evenly. This technique ensures that all airspace, surfaces, and objects are disinfected and decontaminated at a microscopic level

Fogging Technology Comparison

| Technology | Droplet Size | Key Features | Best Uses | Pros | Cons |

|---|---|---|---|---|---|

| DryDecon Submicron Aerosol (<1 μm) | 0.1 – 0.9 μm | Sub-micron aerosol penetrates small spaces, decons the air and does it faster due to increased decontamination surface area of particles. | Complete Air, Surface, Fabric, Electronics, Porous Surface decontamination in any enclosed space including all uses listed below. | Completely decontaminates including the air, surfaces and deep within complex fabrics and materials. | – Less product required – Less labor required – No worries remaining – Completely disruptive decontamination technology |

| ULV (Ultra-Low Volume) Fogging | 2.5 – 20 μm | High-velocity mist; combines air and surface coverage | Farms, warehouses, offices | – Efficient for surface disinfection | – Wets surfaces – Large droplets block smaller spaces – Incomplete air disinfection |

| Dry Fogging (Thermal or Cold) | 1 – 10 μm | Vapor-like mist, low moisture | Clean rooms, poultry, hatcheries | – Minimal moisture – Effective in enclosed spaces | – Inconsistent particle size – Larger droplets, block smaller spaces – Excessive heat alters decontaminant’s effectiveness |

| Electrostatic Sprayers | 30 – 100 μm | Electrically charges droplets to “wrap” around surfaces | Equipment, walls poultry cages | – High surface coverage – Clings to 3D surfaces | – Poor air disinfection – Larger droplets, block smaller spaces |

| Traditional Misting Systems | 20 – 100+ μm | Simple nozzle-based spry | Cooling, dust control | – Inexpensive – Easy setup | – Very large droplets – Poor air disinfection – Leave residue and wetness |